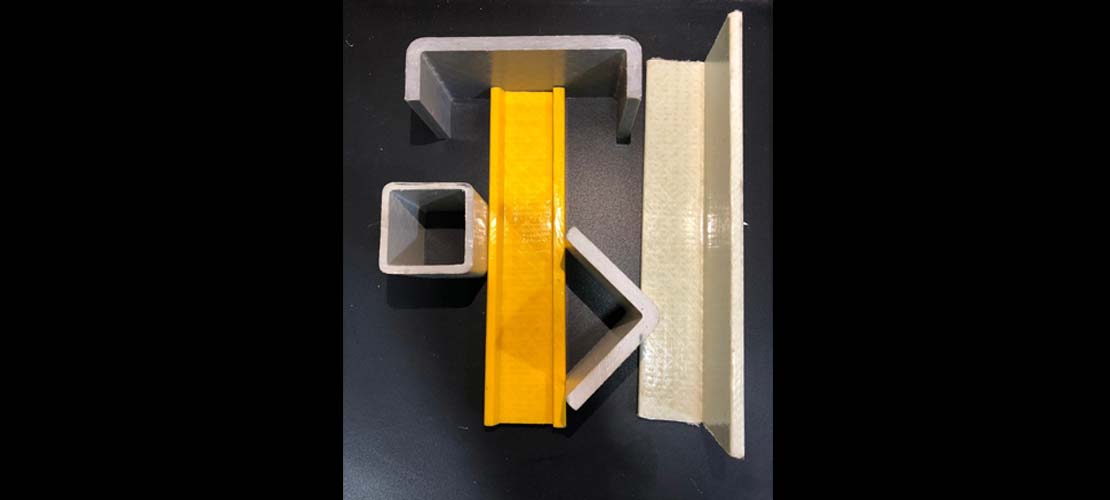

Why Consider Custom Profile ?

A custom part manufactured by Thinkgreen can be an excellent solution to a wide range of problems in practically any application where standard materials or other fiberglass shapes do not meet the needs of the customer. A custom profile should be considered when a unique shape is needed and/ or when the properties of other materials are not suitable for the application.

Thinkgreen can work with the customer to develop custom profiles/parts designed specifically for the application, resulting in better performance, increased reliability and lower life cycle costs associated with the custom profile. Parts consolidation and the competitive advantage that a proprietary design can bring are also attractive reasons to consider a custom profile.

Benefits of Custom Profiles

- Designed specifically for the application

- Provides better performance

- Provides increased reliability

- Results in lower life cycle costs

- Allows for parts consolidation

- Creates a competitive advantage

Combined with the broadest range of profile/part design and engineering expertise, Thinkgreen offers more custom capabilities than anyone in the industry.